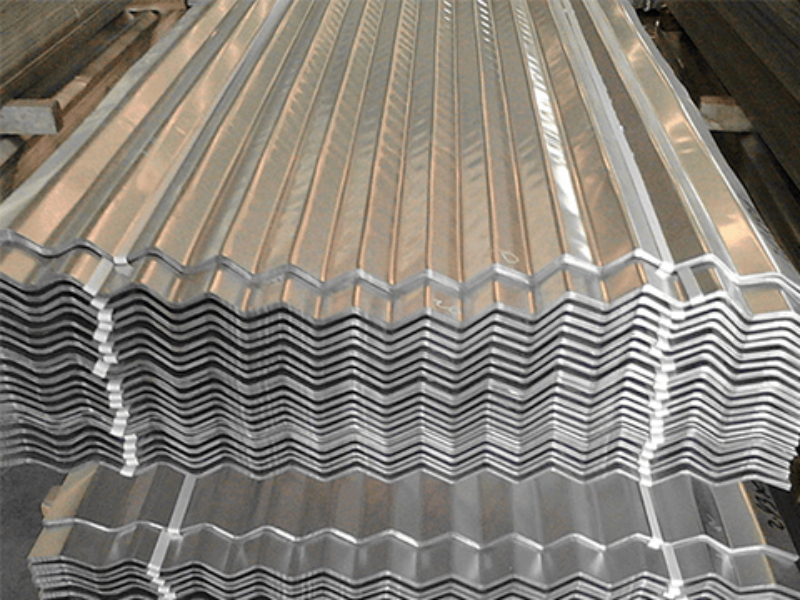

Why Choose Corrugated Roof Sheets?

There are so many materials available on the market, but why are roofing sheet so popular? Their corrugated shape can withstand rain, snow, wind, and frost, offering both aesthetic appeal and lightweight durability. Also known as profiled sheets or corrugated metal roofing panels.

For guidance on selection, you can contact us for more information. Below is a detailed explanation of why you should choose zinc roof sheet.

·They are lightweight

It weighs 6–14 kilograms per square meter, equivalent to one-thirtieth of a brick wall. Compared to traditional building materials, corrugated steel roofing panels are lighter, which helps reduce the load on the building structure and lower construction costs. Additionally, due to their lightweight nature, corrugated steel roofing panels are also easier to install and transport.

·They have high strength and durability

The metal roofing sheet is made of high-strength steel, offering excellent resistance to pressure, wind, and snow loads. This material can withstand extreme weather conditions such as strong winds, rainstorms, and heavy snowfall, thereby protecting the building from damage.

·They have excellent corrosion resistance

The iron sheets roofing is treated with galvanizing or other protective chemical coatings to prevent algae growth. At the same time, they have excellent corrosion resistance and are not easily corroded during long-term use. It can still be restored to its original state after cleaning. If the service life exceeds 30 years, it can shorten the construction period by more than 40%.

·They are aesthetically pleasing

The corrugated roofing sheets plate has a unique appearance and rich colors, which can enhance the beauty of the building. In addition, it can be customized according to building needs to meet the requirements of different architectural styles.

·Their shapes and colors are customizable

Compared to other materials, it has a beautiful appearance, is suitable for different scenarios, and offers a variety of shapes and colors to choose from. At Junnan, you can choose colors based on the RAL color chart and support customization. The shape can be customized according to the needs. We have professional equipment for precision machining and strict quality control.

Common waveform sine wave (arc wave): The roof slab with a sine waveform presents continuous undulations, similar to the waveform of a sine curve. This design has better drainage performance and can effectively disperse the loads of wind and snow.

Trapezoidal wave: a ripple shape with a trapezoidal cross-section, with a shorter upper base and a longer lower base. This design gives the roof slab high strength and is suitable for large-span structures.

Curved wave: presenting a soft curved shape with an elegant appearance. Not only beautiful, but also provides good thermal insulation performance.

·V-shaped Ripples: Sharp V-shaped ripples help with quick drainage and reduce damage to the roof from accumulated water.

·U-shaped ripple: The U-shaped ripple roof panel has a U-shaped cross-section, shaped like the inverted letter U. This design gives the roof panel higher rigidity and stability.

· Composite ripple: The composite ripple roof panel is composed of various ripple shapes and can be customized according to building requirements and design styles. This design has a high degree of flexibility and personalization.

· Diamond shaped ripple: visually pleasing, diamond shaped ripple helps with quick drainage, has high strength and stiffness, and superior insulation performance. In addition to the above shapes, there is also a sandwich board with foam in the middle, which is also the user's choice.

For comprehensive solutions in steel building material, please contact Junnan Steel via email at yy@tsjunnan.com or WhatsApp at (+86) 13780503368 for immediate assistance!