GLOBAL CHOICE · ONE-STOP SUPPLIER

steel, machinery,plant construction,digital and integent industrial chain base

Contact us now

Contact us now

Application

H Beam

An I-beam, also known as H-beam (for universal column, UC), w-beam (for "wide flange"), universal beam (UB). Is a beam with an I or H-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". I-beams are usually made of structural steel and are used in construction and civil engineering.

Application: H beam and I beam can be found just about anywhere heavy duty weight support is required. They often support the main structure of a house and are commonly used under load bearing walls. They cost more to manufacture than a wooden beam, but provide great advantages in terms of strength.

Steel Angle

Steel Angle is the most basic type of roll-formed steel. They are formed by bending a single angle in a piece of steel. Angle Steel is ‘L’ shaped; the most common type of Steel Angle is 90 degree angle. The legs of the “L” can be required equal or unequal in length.

Application: Steel angles are used for various purposes in a number of industries. Framing is one of the most common application for steel angles, but steel angles are also used for brackets, trim, reinforcements, and many other uses. The larger the steel angle, the more weight and stress it can bear.

Steel Sheet Piles

Steel sheet piles are an edge with linkage, and this linkage can be freely combined to form a tightly retaining or retaining wall steel structure. Common are Larson style and Lackawanna style.

Application:The use of steel sheet pile is very wide. It can be used on wharves, unloading yards,embankments, retaining walls, breakwaters, diversion dikes,docks and gates in permanent structures.For temporary structures, it can be used for sealing the mountain, temporarily expanding the bank, cutting off flow, building cofferdams, laying large-scale temporary canalditches, retaining water and retaining sand; in flood control, it can be used for flood control, anti-collapse, anti-sand and so on.

The following are some of the more common applications of steel sheet pile: cofferdam,river diversionand control, water treatment system fence ,flood control ,protective dike ,tunnel cutouts and tunnel shelters.

Wire rod

Wire rod is a kind of hot rolled alloy or non-alloy steel product, produced from a semi (e.g. bloom) and having a round, rectangular or other cross-section. Particularly fine cross-sections may be achieved by subsequent cold forming (drawing). Wire rod is wound into coils and transported in this form.

Application: Wire rod is used for many different products. Depending upon how it is cold formed and heat treated, wire rod can be widely used, for example, to produce not only wire ropes, barbed wire, wire mesh and nails, but also springs, welded wire mesh and reinforcement wire.

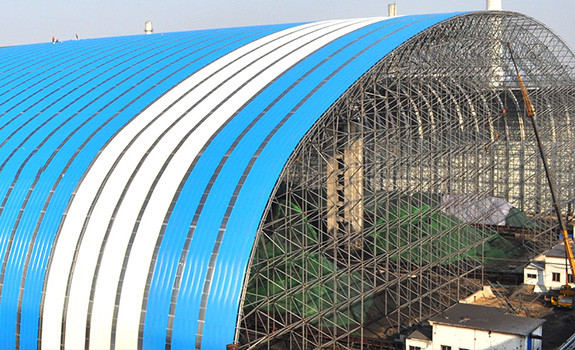

Color coating

PPGI is pre-painted galvanized iron, also known as pre-coated steel coil, coated steel, color coated steel etc., typically with hot dip zinc coated steel substrate.PPGI refers to factory pre-painted zinc coated steel, where the steel is painted before forming, as opposed to post painting which occurs after forming.

Application:

Color coated steel coil/sheet (PPGI &PPGL) is widely used in:

Construction:Architects and buildings owners are increasingly turning to prepainted metal to match their design vision for commercial and residential installations.

Transportation:The transportation goods industry encompasses several different product types, all of which have or can benefit from the use of prepainted metals by not only streamlining the manufacturing process, but by drastically reducing production costs.

Appliances:Appliance manufacturers are turning to prepainted coil in increasing numbers for several compelling reasons:lower cost solution, more consistent product, team approach to innovation and problem-solving (manufacturer/coater/coating supplier).

We will get you best and fast quotation in 24 hours .